Lvyuan: sintered products

Research

PE Sintered Silencer & Mufflers: An Overview

PE sintered silencers and mufflers are widely used noise control devices in various industries. They are designed to reduce the noise generated by mechanical systems, engines, and industrial equipment. This article provides an overview of PE sintered silencers and mufflers, highlighting their construction, working principle, and applications.

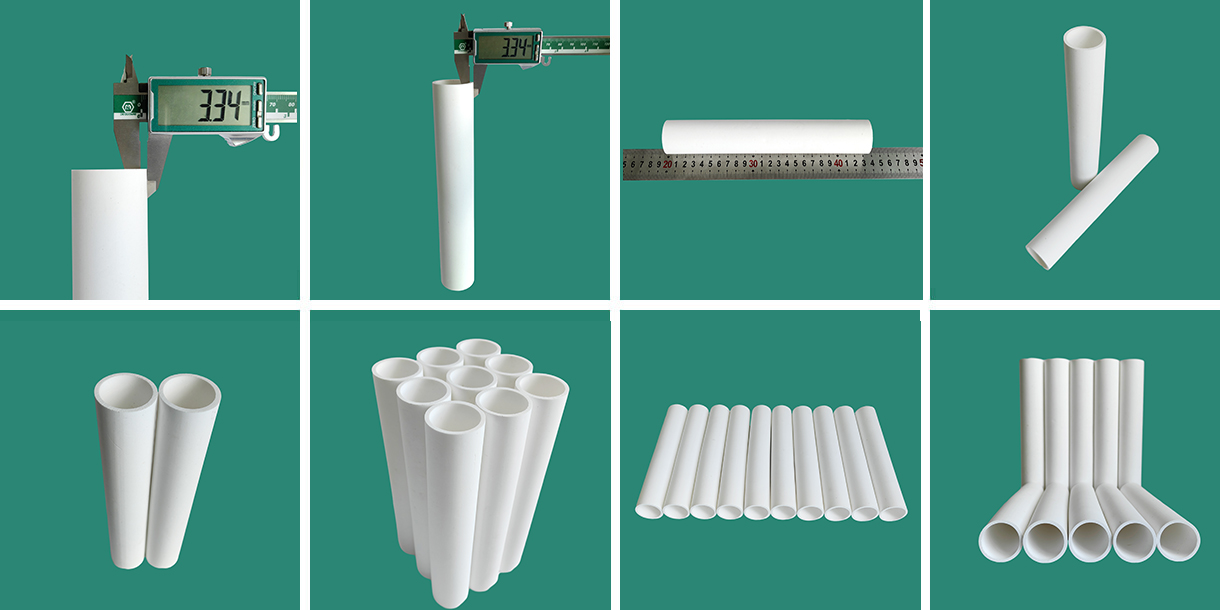

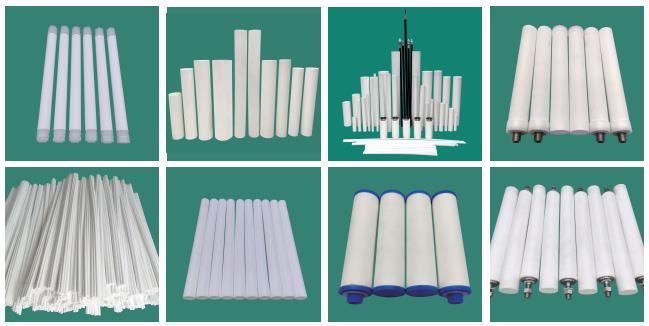

Construction: PE sintered silencers and mufflers are made from high-quality polyethylene (PE) materials that are processed using the sintering technique. The sintering process involves compacting and heating the PE particles to form a solid, porous structure with interconnected voids. This porous structure acts as a sound-absorbing medium.

Working Principle: When high-pressure gas or air flows through the PE sintered silencer or muffler, the sound waves generated by the turbulent flow encounter the porous structure. These sound waves penetrate the porous medium, where they undergo multiple reflections and encounters with the solid walls of the pores. This interaction causes the sound energy to dissipate, resulting in noise reduction.

The interconnected voids in the sintered structure of the silencer or muffler play a crucial role in noise attenuation. The size and distribution of these voids can be adjusted during the manufacturing process to achieve specific noise reduction characteristics.

Applications: PE sintered silencers and mufflers find applications in various industries where noise control is essential. Some common applications include:

Automotive Industry: PE sintered mufflers are used in exhaust systems of automobiles to reduce the noise produced by the engine exhaust gases. They help comply with noise pollution regulations while ensuring smooth engine operation.

Industrial Equipment: PE sintered silencers are employed in pneumatic systems, compressors, blowers, and other industrial equipment to minimize noise levels. They contribute to creating a quieter working environment and comply with occupational health and safety standards.

HVAC Systems: PE sintered silencers are utilized in heating, ventilation, and air conditioning (HVAC) systems to reduce noise generated by fans, blowers, and air handling units. They enhance indoor comfort by minimizing unwanted noise levels.

Power Generation: PE sintered mufflers are commonly used in power generation plants, such as gas turbines and diesel generators, to attenuate noise emitted during operation. This ensures compliance with environmental regulations and minimizes disturbance to nearby residential areas.

Benefits: PE sintered silencers and mufflers offer several advantages, including:

Noise Reduction: They effectively reduce noise levels generated by machinery and equipment, contributing to a quieter environment.

Durability: PE sintered silencers and mufflers exhibit excellent resistance to corrosion, chemicals, and high temperatures, ensuring long-term performance.

Design Flexibility: These devices can be manufactured in various shapes, sizes, and configurations to suit specific application requirements.

Easy Installation: PE sintered silencers and mufflers are designed for easy installation, making them convenient for retrofitting into existing systems.

Conclusion: PE sintered silencers and mufflers play a crucial role in noise control across different industries. Their ability to reduce noise levels, durability, and design flexibility make them indispensable for creating quieter environments and meeting regulatory requirements. Whether in automotive, industrial, or power generation applications, PE sintered silencers and mufflers provide effective noise attenuation solutions.

Guangzhou Lvyuan Water Purification Equipment Co., Ltd.

Write Message to Company.