Lvyuan: sintered products

Lvyuan News

Custom Sintered PTFE Porous Filters for Liquids and Gase

Sintered PTFE is made by molding and heating fine PTFE resin particles until they fuse into a porous structure. This creates a hydrophobic filter material with controlled pore sizes ideal for filtering liquids and gases.

The sintering process allows PTFE filters to achieve:- High porosity up to 90% void volume for maximum flow rates

- Pore sizes ranging from 0.1 to 150 microns for precise particle retention

- Strength and durability from the fused PTFE particles

- Chemically inert, hydrophobic material resistant to almost all chemicals

Key Benefits of Sintered PTFE FiltersSintered PTFE filters provide:- Extreme chemical resistance. Withstands even the most aggressive acids, bases, oxidizers, hydrocarbons, and solvents.- Repels liquids. Hydrophobic material prevents liquid ingress into pores during filtration.- High temperature rating. Stable up to 500°F with excursions to 550°F.- Compliant construction. Pliable PTFE conforms to seal housings.- High flow rates. High void volume reduces pressure drop during operation.- Easy cleanability. Smooth non-stick PTFE surface prevents particle adhesion.

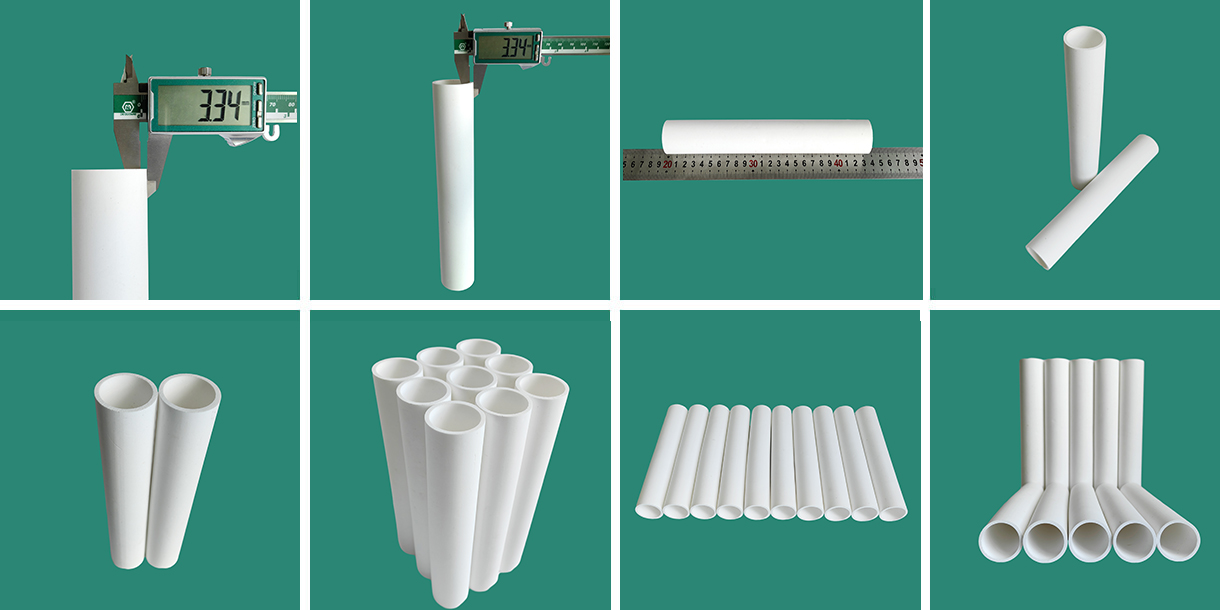

Customizing Your Sintered PTFE FilterOur sintered PTFE filters are fully customizable:- Micron ratings from 0.1 to 150 microns

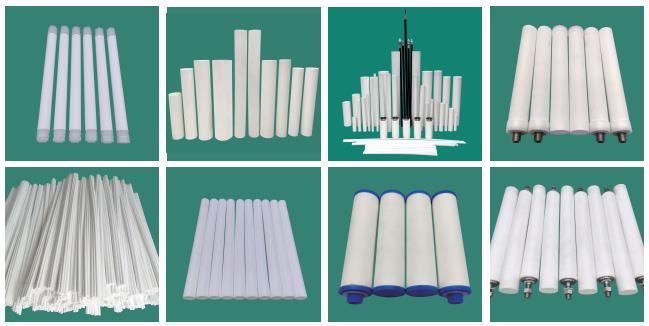

- Cut into sheets, tubes, discs, cylinders or custom shapes

- Available in any size or dimension up to 60” diameter

- Integrated into cartridges, capsules, housings and filter bags

- Validated, documented and certified for regulated industries

Contact our engineering team to optimize a sintered PTFE filter for your specific liquids or gases. We can provide the ideal filtration solution for your application!

Guangzhou Lvyuan Water Purification Equipment Co., Ltd.

Write Message to Company.