Lvyuan: sintered products

Lvyuan News

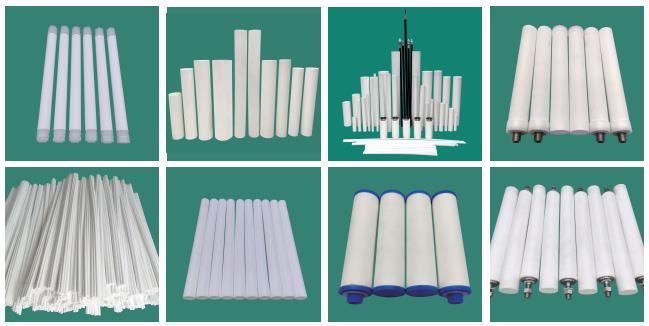

PE SINTERED FILTER ELEMENT FOR WATER, OIL, AIR AND DUST FILTRATION

PRODUCT PERFORMANCE

1.Material properties: PE with UHMWPE as the main medium has the characteristics of non-toxic, tasteless, no

foreign matter dissolution, and biochemical safety.

2.Chemical properties: PE filter media has excellent corrosion resistance, and can withstand various non-strong

oxidizing acids, Alkali resistance, aldehyde resistance, aliphatic hydrocarbon resistance, radioactive radiation

resistance, etc., excellent chemical properties, and good resistance to organic solvents. Below 80°C it can resist

ester ketone, ether and other organic solvents;

3. Temperature resistance: the highest Saturated steam temperature can reach 130°C, long-term continuous use

does not exceed 80°C;

4. Mechanical properties: good toughness and strength, impact resistance, not easy to damage,

5. Filtration performance: Filtration accuracy range (0.2-200 microns), high filtration efficiency, controlling the

initial pressure can effectively remove solid particles above 0.2 microns

6. Physical properties: The specific gravity of the medium is light, and the theoretical specific gravity is around

0.5-0.7g/ml ;

7. Regeneration performance: The capillary pores of PE media have the elasticity of microscopic expansion, and

can be efficiently reversed and regenerated by water pressure, air pressure or water-air pressure. Ensure that it

can use the acid solution of appropriate concentration to chemically dissolve and regenerate the blockage, so that

the filtration performance of the medium can be restored to the original state, and the service life of the quality can

be improved;

8. Processing performance: Secondary processing can be carried out by turning, milling, planing, ironing, hot-melt

welding, bonding, etc.;

9. Basic characteristics: It is manufactured by a special sintering process, in which plastic particles are heated to

its surface until soft, and melts on the contact surface while approximately retaining its original shape. The resulting shaped body has open continuous pores, the size and number of which depend on the sintering conditions

and the size selection of the polymer particles.

PRODUCT FEATURE

1. Large flow: high porosity (around 50%) ensures greater fluid flow per unit area;

2. Smooth surface: smooth surface, impurities are not easy to stick, backwashing is easy and thorough, and can

be reused;

3. Strong anti-fouling ability: high filtration accuracy makes it difficult for impurities to remain in the filter body, and

can press the sludge to a water content of 70%;

4. Excellent cost performance: the filter element has excellent comprehensive performance and high cost performance, and is suitable for water treatment, environmental protection sewage treatment, reclaimed water reuse,

chemical product filtration and other working conditions with large flow;

5. Resistance to strong acid and strong alkali corrosion, Resistance to various high temperature and strong corrosive chemical raw materials filtrations, and resistance to dissolution of organic solvents;

6. Excellent strength and wear resistance ensure its service life;

7. The surface of outer light makes it difficult for impurities to stick together,

8. Good toughness, the filter element is not easy to break;

9. No threshing phenomenon;

10. Strong pressure resistance

APPLICATION

PE sintered microporous filter element can be used as a filter medium for heterogeneous phase separation

(solid-liquid, gas-solid, gas-liquid, liquid-liquid) in a physical sense.

1.Used for solid-liquid separation: the application of clarification filtration or filter plate filtration, the filtration efficiency of solid particles above 0.2 microns can reach more than 99.7%.

(1) Application in the field of pharmaceuticals and food: such as the filtration of liquid medicine for injections in the

production of injections in the pharmaceutical industry and the filtration of bottled water for washing injections;

Separation and filtration of tetracycline production; fine filtration of corn oil, soybean oil, rapeseed oil and other

edible oils.

(2) Application in the field of environmental protection water treatment: such as the purification and filtration of

heavy metal salts in electroplating solutions and industrial heavy metal wastewater in the electroplating industry,

and the wastewater containing cadmium, copper, chromium, nickel, lead, etc., is chemically treated and then

filtered through PE microporous tubes. Emission, filtration and recycling of coal-containing wastewater, flue gas

water liquid desulfurization filtration, dry dust recovery, purification and filtration of electrodialysis water;

(3) Application in chemical industry: precision filtration of liquid products, liquid raw materials and liquid intermediates in chemical production, such as precision filtration of various acids, alkalis, salts and most organic solvents,

acid and sulfur filtration in chemical fiber production , brine filtration in the production of chlor-alkali industry, activated carbon filtration in glyphosate production, filtration of barium sulfate and potassium hydroxide in metallurgical

plants, photosensitive film production, and can also be used as plate and frame filter press, after centrifuge and

other precision filter.

(4) Application in the field of non-ferrous metals: such as nickel chloride, cobalt chloride, nickel oxalate, cobalt

carbonate, nickel carbonate and other non-ferrous metals during the preparation of non-ferrous metals, such as

decalcification and iron filtration of pickling solution, and filtration and washing of crystallization solution.

2.For gas-solid, gas-liquid separation:

Used for the filtration of ammonia gas separation dust, water droplets and oil droplets in melamine production;

compressed air purification and filtration; air separation dust filtration in watch production; in short, it can be used

for purification and filtration of various gases to separate solids, oil droplets and water droplets, etc. .

3.Used for liquid-liquid separation:

(1) It can be used to filter foreign matter such as oil droplets in water. After filtering, the oil content in wastewater is

only about 2ppm, which is much lower than the national standard.

(2) Used as a liquid dispersion bubbler: the porous PE pipe body is an ideal gas bubbler; it can be used as an air

or ozone dispersion bubbler in a sewage biochemical treatment system; an air bubbler in a mine beneficiation

system, Gas dispersion bubbler in gas absorption operation; it has been used in wastewater treatment and beneficiation systems at home and abroad.

(3) As a gas muffler: porous PE pipe is an excellent gas muffler.

4. Other uses:

(1) Porous PE pipe or plate can be used as a support for reverse osmosis and ultrafiltration membranes.

(2) The porous PE plate can be used as the separator of the dielectric tank.

(3) The porous PE plate can be used as a gas distributor (fluidization plate) in the airflow conveying of powdery

materials.

(4) Porous PE pipe can be used as gas diffuser and aeration.

(5) Porous PE sticks or sheets can be used as liquid storage and scent diffusion (perfume and liquid mosquito

coils).

(6) Porous PE pipe can be used as air diffuser and oxygenation for aquarium fish tanks.

(7) The porous PE filter can be used as a watercolor pen tip.

(8) Porous PE filter can be used as flower pot water absorbing rod, flower pot water absorbing support frame

(9) The porous PE filter can be used as a temperature sensor, smoke detection, and online monitor protector

INSTRUCTIONS

Porous PE pipe or plate can be used for vacuum filtration, pressure filtration or gravity filtration. In order to

use this product well, the following points must be mastered:

1. Correct selection of filtration parameters (optimum filtration pressure difference, filtration speed and filtration

area, etc.), therefore, a small test to determine the design parameters must be carried out in advance.

2. According to the requirements for filtration in production and the characteristics of porous PE media, the

mechanical structure of the filter should be correctly designed.

3. There must be certain operating procedures during use, especially at least 5-10 minutes of low-pressure 0.3-0.5

kg/

filtration at the start-up stage. It is forbidden to reach the normal operating pressure as soon as it is started,

otherwise the capillary pores will be blocked too quickly, which will significantly reduce productivity.

4. The porous PE filter should be equipped with a certain volume of air bags (one air bag can be used for several

filters) for back blowing slag removal and back blowing regeneration. The back blowing pipeline should be thicker

and the back blowing valve Ball valves or cocks should be used, the blowback speed should be fast, and the blowing time should not be long, generally no more than 1 second, otherwise the compressed air will be wasted.

5. According to the characteristics of different materials, different regeneration operation procedures should be

formulated.

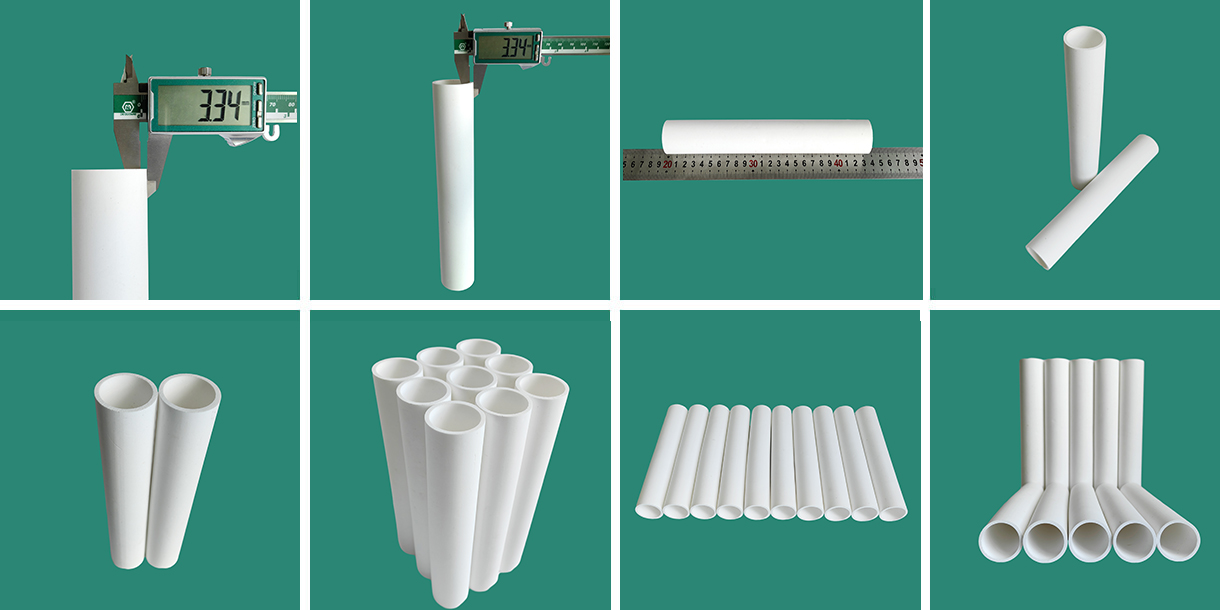

PARAMETERS

1. Working temperature: UHMWPE 80°C, PA 120°C

2. Working pressure: 0.1MPa-0.6MPa

3. Filtration accuracy: 0.2μm to 200μm

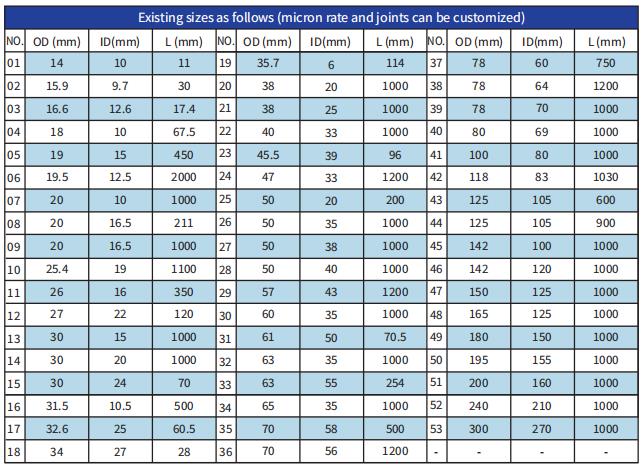

*LVYUAN currently has PE filter elements of the following size:

*More specifications and styles can provide non-standard customization.

Guangzhou Lvyuan Water Purification Equipment Co., Ltd.

Write Message to Company.